Chameleon Foundry

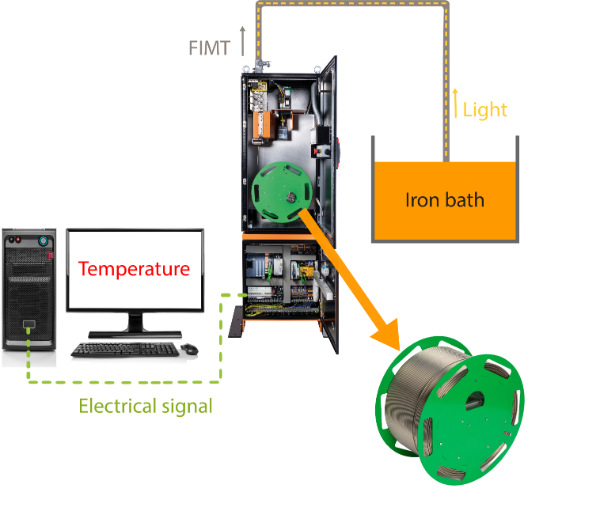

Chameleon Foundry is a precision temperature measurement system designed for foundries, it can measure in the pouring line, holding furnace and ladle. It uses an automated, optical fiber-based measuring system to deliver accurate temperature readings of liquid iron.

Benefits

- Automated Measurement: Streamline operations with precise, automated temperature assessments.

- Increase safety because Chameleon Foundry is operated from the control room, or from a save distance, during the process.

- Reduce human error and eliminate uncertainty associated with operator practices.

- Improved Process Control: Achieve superior management of foundry processes with enhanced temperature monitoring.

- Temperature Stability: Maintain better control with reduced fluctuations in temperature.

- Consistent Measurement Accuracy: Ensure precise temperature readings in the same spot for better reliability.

- Casting Measurement Capability: Chameleon Foundry has capability of measuring every mould accurately with seamless integration to the moulding line.

- Decrease Carbon Footprint: Precise temperature measurements enhance process stability. It will also help to reduce scrap, and optimise energy consumption as well as eliminating paper tubes of the thermocouples. Less transportation will also reduce the carbon emission.

- High Measurement Capability: One coil can measure up to 6000 times.

- Optimized Energy Consumption: Maximize energy efficiency throughout the foundry process.

- Efficient Inventory Management: Reduced logistical burden leads to improved inventory management.

The Chameleon Foundry utilizes an automated, optical fiber-based measuring system to deliver accurate temperature readings of liquid iron.

The system consists of two primary components: the feeder unit and the control unit. PC and monitor setup are located inside the control room for user interaction.

Feeder Unit

- The feeder unit houses all the mechanical parts needed for measurement. Key components include the coil holder, feeder, and straightener.

- The coil holder rotates to wind the wire onto the feeder. The feeder securely grips and feeds the wire into the molten iron. Meanwhile, the straightener guarantees that the wire maintains its straightness as it exits the guiding tube.

Control Unit

The control unit, located below the feeder unit, contains the electronics to operate the system. Importantly, the feeder and control unit can be separated. This offers several advantages:

- Temperature Management: If the temperature near the feeder is too extreme, the control unit can be moved to a safer location.

- Height Flexibility: This design allows us to reduce the height of the system, which can be crucial in space-limited installation areas.

- Cost Efficiency: We can connect multiple feeder units to one control unit, significantly reducing the overall costs.

Technical Data

|

Item |

Description |

|---|---|

| Measurement application | Temperature measurement on demand |

| Measurement channel | One analog input |

| Measurement ranges | 1300 - 1600°C |

| Display resolution | 1° |

| Display units | °C or °F |

| Power supply | 3x400VAC + N + PE / 50-60Hz |

| Weight instrument | 370kg |

| Coil outer diameter | 460mm |

| Coil depth | 249mm |

| Max coil length | 630m |

| Max coil weight | <25kg |