Innovations

FalconTM

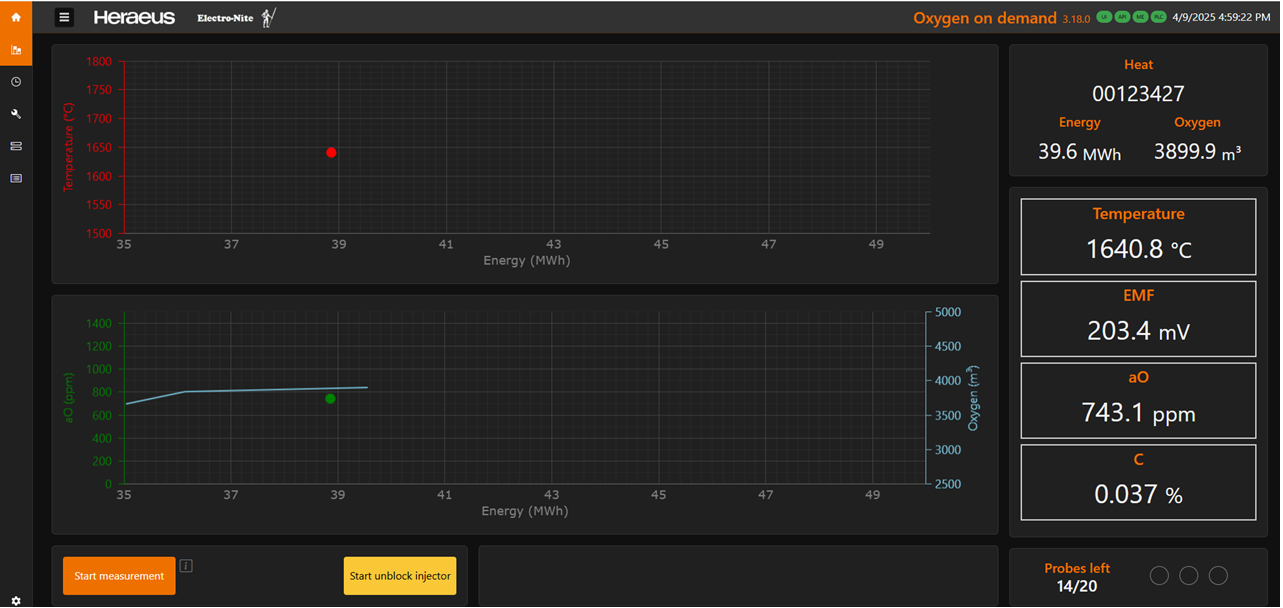

Manless, on-demand temperature and oxygen measurements for EAF process optimization

Falcon is an automated measuring system capable of delivering accurate temperature, oxygen and carbon readings of liquid steel during the operation of electric furnaces. It is the fastest oxygen and temperature combined measurement on the market, developed to withstand the harsh environment around the electric arc furnace.

Safe and fast measurement helps an EAF operator accurately determine when temperature and oxygen end points will be reached to maximize EAF efficiency.

Benefits

- Increase safety : Operated from the control room, the fully automated oxygen measurement system fits the current safety standard of no man on the floor.

- Increase Yield: Early and multiple possible oxygen measurements allows to a controlled and tuned carbon and oxygen injection minimizing iron overoxidation and decreasing iron losses.

- Energy Efficiency: The Falcon solution conducts “Closed Slag-door” measurements, ensuring optimal operation with a maximum foamy slag state, thereby enhancing the system's energy efficiency.

- A lower electrical consumption

- More efficient utilization and consumption of graphite electrodes

- Lower refractory consumption due to improved thermal transfer from the electrodes to the steel bath

- Improved quality

- Gives insight in dephosphorization conditions

- Substitution of complex, unreliable and expensive robots

System Information

The Falcon system consists of different components:

- The manipulator, which is a pneumatic based system that holds and, at the operator’s request, launches measuring sensors into the EAF

- The Pneumatic unit powers the manipulator, providing the necessary pneumatic force to operate the system smoothly and reliably.

- The PLC control unit controls and manages all system components with the ability to be accessed remotely by multiple users.

- Designed to hold and supply 20 Falcon probes

- Quick reloading capability: A new drum with probes can be reloaded in just one minute, ensuring minimal downtime and continuous operation.

Technical Data

|

|

Description |

|---|---|

| Application | Temperature, oxygen and carbon measurement in EAF |

| Measurement input | Two analog inputs |

| Measurement range | |

| Temperature | 1500…1850°C (2732 to 3362°F), type C |

| Oxygen | 150…2000ppm |

| Measurement accuracy | |

| Temperature | ± 10 °C |

| Oxygen | ± 5 mV |

| Calculated values | carbon, aluminum in kg to kill steel, slag %FeO, amount of O2 to reach aO target, steel bath homogeneity (in combination with Chameleon) |

| Different hardware components: | |

| Falcon launcher | |

| Dimensions | 701x1400x422 mm (HxWxD), 140 kg |

| Operating ambient temperature range | -20°C (-4°F) to 60°C (140°F) |

| Air flow: continuously for cooling | 200 l/min |

| Air flow: during the probe launch | 3200 l/min (2900…5000 l/min) |

| Falcon Pneumatic Unit | |

| Dimensions | 1400x800x300 mm (HxWxD), 110 kg |

| Compressed air | 3 to 6 bar |

| Power supply | 24 V DC (from control unit) |

| Falcon Control Unit | |

| Dimensions | 1200x800x400 mm (HxWxD), 120 kg |

| Power supply | 3x400VAC+PE / 50-60Hz / 16 A / max. 4 KW |

| Dust/moisture protection class | IP 54 |

| Level2 communication protocols | Profibus, Profinet, Ethernet IP, Modbus TCP |